Operating office: Via Comunità Carnica 7, 33029 Villa Santina UD . t. +39 0433 86075 . info@lumieimpianti.com

Design your plant

Run-of-river

hydroelectric power plants

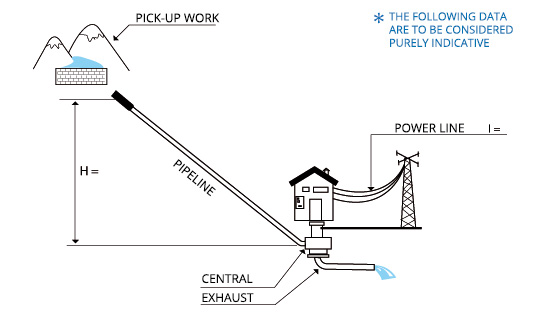

A run-of-river hydroelectric power plant consists of civil and hydraulic works and electromechanical equipment and is built to convert the potential energy of water flowing from a higher point than the level of the turbines.

The two main factors for determining the power that can potentially be generated are:

- head: the difference in height between the location of the water resource and the point of outlet;

- flow rate: the amount of water available for the turbine, net of the discharge (MVF) required by law.

A typical plant consists of:

- barrage: riverbed construction whose purpose is to convey water towards the settling tank;

- settling tank: engineering works consisting of a suitably sized tank where sand can settle. They are usually fitted with a mechanical sluice gate to facilitate cleaning;

- mechanical screen: placed between tanks to filter suspended matter in the water;

- settling tank: civil works positioned immediately after the mechanical screen at the start of the penstock feeding into the turbine; fitted with a mechanical sluice gate to facilitate cleaning;

- penstock: pressurised pipeline made of different materials, which carries water from the intake to the powerhouse;

- powerhouse: building designed to house electromechanical equipment;

- electromechanical equipment: this transforms potential energy into prime mechanical energy, through rotation of the turbine, and then into electrical energy via the generator and the electrical turbine and grid connection switchgear;

- outlet works: hydraulic canal returning water to the river.

The main feature of run-of-river plants is that there is no upstream storage tank and therefore power cannot be regulated according to demand. This means that production varies according to the flow rate of the water and its seasonal availability. These hydraulic plants provide excellent profit potential, while having a lower environmental impact and construction costs than pondage plants.